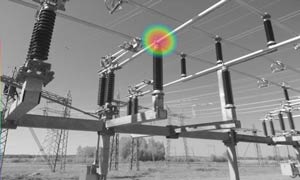

Lightweight and easy-to-use, this industrial acoustic imaging camera uses 124 microphones to form a precise acoustic image and cloud analytics for insights of partial discharge. With a frequency range of 2 to 35 kHz, this camera detects leakage from a distance and enables the user to fix problems and validate in real-time.

Lightweight and easy-to-use, this industrial acoustic imaging camera uses 124 microphones to form a precise acoustic image and cloud analytics for insights of partial discharge. With a frequency range of 2 to 35 kHz, this camera detects leakage from a distance and enables the user to fix problems and validate in real-time.

Discontinued!

This product has been discontinued and is no longer available.

This is the direct replacement:

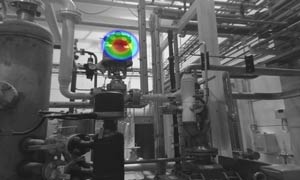

An easy-to-use, stand-alone system for locating pressurized leaks in compressed air systems. This lightweight, one-handed solution is designed to help maintenance, manufacturing, and engineering professionals identify air leaks up to 10 times faster than with traditional methods. Built with 124 microphones, this acoustic imaging camera produces a precise acoustic image that visually displays ultrasonic information, even in loud, industrial environments.

The acoustic image is overlaid in real-time on a digital camera picture, allowing the user to pinpoint the source of the sound accurately. Equipped with the Acoustic Camera Viewer cloud service, this intelligent tool automatically saves images to the cloud. Users can then access stored files and separate sound sources for deeper analysis and classification of problems. Through a regular maintenance routine, this camera can help facilities save money on utility bills and delay the expense of installing new compressors.

Find leaks faster

Detect compressed air leaks up to 10 times faster with ultrasonic imaging vs. traditional methods.Reduce costs, save money

Minimize excess costs resulting from compressed-air leaks.Inspect easily

Quantify the severity of air leaks in real time with this smart, convenient tool.Applications

| Acoustic | |

| Measurement | 124 low-noise MEMS microphones, real-time sound visualization |

| Sensitivity, Accuracy | <-15 dB (frequency-dependent) |

| Dynamic Range | >120 dB (frequency-dependent) |

| Bandwidth | 2 to 35 kHz, adjustable range |

| Distance | From 1.0 up to 430' (0.3 up to 130 m) |

| Leak Rate | In typical industrial environment: >0.032 l/min at 3 bar from 9.8' (3 m) >0.05 l/min at 3 bar from 32.8' (10 m) Absolute minimum detection in quiet environment: 0.016 l/min at 1.2 bar from 1.0' (0.3 m) |

| User Interface | |

| Display | Size: 5" 800 x 480 Color: 24-bit RGB Brightness: 1000 cd/m2 (adjustable) |

| Input Device | Resistive touchscreen |

| Power On Indicator | Red LED |

| Video | Image resolution: 800 x 480 Frame rate: 25 fps |

| Acoustic Image Frame Rate | 30 fps |

| Zoom | 2x digital zoom |

| Communication and Data Storage | |

| Wireless Data Transfer | Wi-Fi 2.4 GHz and 5 GHz IEEE 802.11.b/g/n/ac wireless LAN |

| Storage | Internal: 32 GB/2000 snapshots (typical) on non-removable SD card External: 8 GB/500 snapshots (typical) on USB mass storage, provided with device |

| General Specifications | |

| Power Supply | Nominal input voltage: 12 V Maximum input: 15 V, 2.5 A External battery: LiFePO 12 V 7 Ah, 84 Wh Usage: Up to 7 hours (depends on ambient conditions) Charge time: 4 to 6 hours Internal battery: Li-Ion 6 Wh (only for camera backup use) |

| Operating and Storage Temperature Range | Recommended: 14 to 122°F (-10 to 50°C) |

| Operating and Storage Humidity | Recommended: 0 to 90% |

| Dimensions | 10.7 x 6.7 x 4.9" (273 x 170 x 125 mm) |

| Weight | 6.4 lbs (2.9 kg) |

| Acoustic | |

| Measurement | 124 low-noise MEMS microphones, real-time sound visualization |

| Sensitivity, Accuracy | <-15 dB (frequency-dependent) |

| Dynamic Range | >120 dB (frequency-dependent) |

| Bandwidth | 2 to 35 kHz, adjustable range |

| Distance | From 1.0 up to 430' (0.3 up to 130 m) |

| Leak Rate | In typical industrial environment: >0.032 l/min at 3 bar from 9.8' (3 m) >0.05 l/min at 3 bar from 32.8' (10 m) Absolute minimum detection in quiet environment: 0.016 l/min at 1.2 bar from 1.0' (0.3 m) |

| User Interface | |

| Display | Size: 5" 800 x 480 Color: 24-bit RGB Brightness: 1000 cd/m2 (adjustable) |

| Input Device | Resistive touchscreen |

| Power On Indicator | Red LED |

| Video | Image resolution: 800 x 480 Frame rate: 25 fps |

| Acoustic Image Frame Rate | 30 fps |

| Zoom | 2x digital zoom |

| Communication and Data Storage | |

| Wireless Data Transfer | Wi-Fi 2.4 GHz and 5 GHz IEEE 802.11.b/g/n/ac wireless LAN |

| Storage | Internal: 32 GB/2000 snapshots (typical) on non-removable SD card External: 8 GB/500 snapshots (typical) on USB mass storage, provided with device |

| General Specifications | |

| Power Supply | Nominal input voltage: 12 V Maximum input: 15 V, 2.5 A External battery: LiFePO 12 V 7 Ah, 84 Wh Usage: Up to 7 hours (depends on ambient conditions) Charge time: 4 to 6 hours Internal battery: Li-Ion 6 Wh (only for camera backup use) |

| Operating and Storage Temperature Range | Recommended: 14 to 122°F (-10 to 50°C) |

| Operating and Storage Humidity | Recommended: 0 to 90% |

| Dimensions | 10.7 x 6.7 x 4.9" (273 x 170 x 125 mm) |

| Weight | 6.4 lbs (2.9 kg) |